- Home

- Course Finder

- Training Categories

-

- Governance and Compliance

- Management & Leadership

- Finance & Accounting

- Agility Learning

- Project Management

- Purchasing & Supply Chain Management

- Manufacturing & Production Management

- Transportation & Traffic

- Imports & Exports

- Insurance & Retirement

- Ports & Shipping

- International Trade & Customs

- Facilities & Asset Management

- Contracts Management

- Maintenance & Engineering

- Oil and Gas Training

- Energy Training

- Health & Safety

- Blockchain & Financial Technologies

- Construction Management

-

- In-House Training

- Venues

-

- Rabat - Morocco

- Al Ain - UAE

- Amsterdam - The Netherlands

- Barcelona - Spain

- Cairo - Egypt

- Dubai - UAE

- Geneva - Switzerland

- Houston - USA

- Istanbul - Turkey

- Jeddah - Saudi Arabia

- Kigali - Rwanda

- Kuala Lumpur - Malaysia

- Lisbon - Portugal

- London - UK

- Luanda - Angola

- Madrid - Spain

- Milan - Italy

- Munich - Germany

- Muscat - Oman

- Nairobi - Kenya

- New York - USA

- Paris - France

- Riyadh - KSA

- Rome - Italy

- Singapore -

- Tokyo - Japan

- Vienna - Austria

- Zurich - Switzerland

- Krakow - Poland

- Moscow - Russia

-

- Certificates

- About Us

A highly interactive training course on

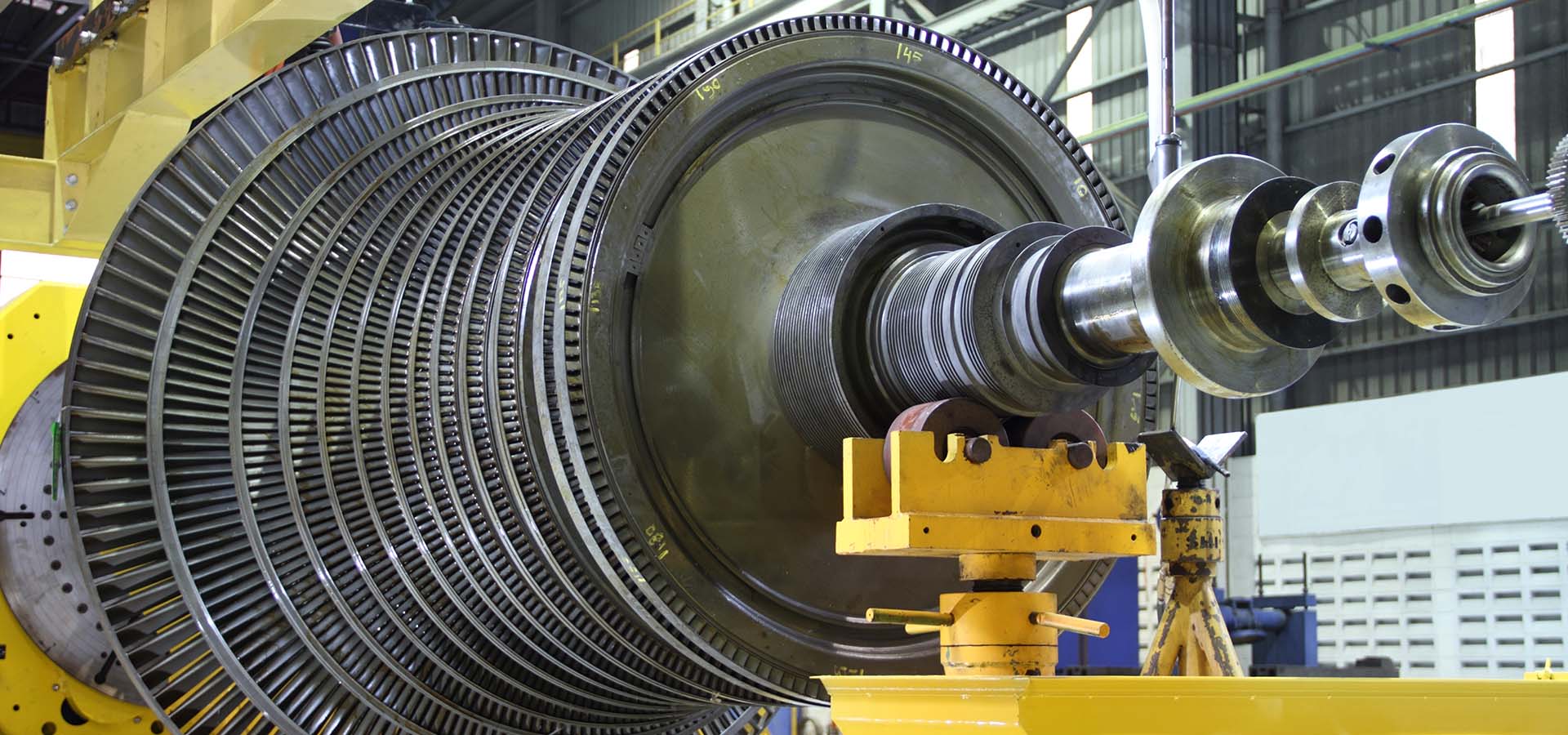

Rotating Equipment:Start-up, Operation, Maintenance & Troubleshooting

Training course overview

This intensive Coventry Academy training course on Rotating Equipment will introduce delegates to elements of rotating equipment as encountered in oil and gas industry. Various types of gas compressors, pumps and turbines will be discussed and the importance of their vital design elements such as bearings, seals, filters, safety controls, and others, will be explained in detail.

The Rotating Equipment training course will be on the start-up and operation of these machines and their optimal maintenance, diagnostics and troubleshooting techniques. The training course will also highlight the guidelines for efficient and safe operation, by indicating the important elements of safety control systems.

This Coventry Academy training course will feature:

- Principles of compressor, pump and turbine start up and operation

- Best practices for maintenance and repair

- Measurement and control of performance of these machines

- Inspection and diagnosing the root cause of problems

- Troubleshooting techniques for operational problems of pumps, compressors and turbines

What are the goals?

By the end of this Coventry Academy training course, participants will be able to:

- Understand operation of various types of compressors, pumps, and turbines

- Operate compressors pumps and turbines close to their design efficiency

- Monitor compressor, pump and turbine reliability and availability

- Combine range of operation and cost effectiveness

- Select the best operation and maintenance strategy

- Troubleshoot compressor, pump and turbine problems

Who is this training course for?

This Coventry Academy training course is designed to benefit all levels of Technical Personnel in the oil and gas industry as well as in chemical and process industries but will greatly benefit:

- Technical Personnel in charge of production

- Maintenance and Operation Engineers

- Operators

- Supervisors

- Engineering Managers

How will this training course be presented?

This Coventry Academy training course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented. This will be conducted along workshop principles, with formal lectures, case studies and interactive worked examples done in the form of team work during the class workshops.

Several real-life case studies and practical exercises will be provided to illustrate the main points presented in the lectures. There will be ample opportunities for class discussion and sharing experience.

Course Outline

Day One: Technical Characteristics of Rotating Equipment

- Rotating Equipment and Safety Requirements for Start-Up and Operation

- Specifics of Gas Compressing and Cooling Methods

- Selection and Application of Gas Compressors

- Design Elements of Centrifugal and Axial Compressors

- Performance of Reciprocating and Rotary Compressors

- Workshop: Case Study, Examples and Solutions

Day Two: Pump Elements and Operating Characteristics

- Specifics of Process of Liquid Pumping Based on Liquid Types

- Selection and Application of Liquid Pumps

- Design Elements and Characteristics of Centrifugal Pumps

- Importance of Suction Pumping System for NPSH and Cavitation

- Performance of Reciprocating and Rotary Pumps

- Workshop: Case Study, Examples and Solutions

Day Three: Gas and Steam Turbines Operating Characteristics

- Industrial Application of Gas and Steam Turbines

- Design Elements and Operation of Gas Turbine

- Combustor Performance and Selection of Fuels

- Steam Turbine Operating Characteristics and Safety Control System

- Cogeneration Process with Gas and Steam Turbine working Together

- Workshop: Case Study, Examples and Solutions

Day Four: Installation, Start-Up and Performance Control of Rotating Equipment

- Installation, Commissioning, Start-Up and Performance Control of Compressors

- Installation, Commissioning and Start-Up of Pumps and Piping Systems

- Start-Up of Gas and Steam Turbines

- Summary of Operation Control and Performance Monitoring of Rotating Equipment

- Workshop: Case Study, Examples and Solutions

Day Five: Inspection, Maintenance and Troubleshooting of Rotating Equipment

- Inspection of Vital Elements of Rotating Equipment and Safety Control

- Common Failures in Operation of Rotating Equipment

- Condition Monitoring and Predictive Maintenance

- Bearing Degradation and Replacement

- Mechanical Seal Problems in Operation and Root Cause Analysis

- Summary and Conclusions

The certificate

- Coventry Academy Certificate of Completion for delegates who attend and complete the training course